Description

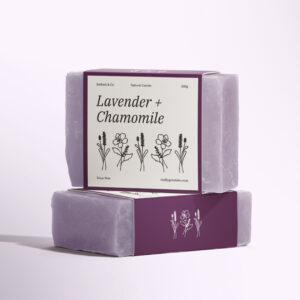

Premium Custom Soap Sleeve Packaging

Soap box sleeve packaging combines the protective benefits of rigid boxes with the branding opportunities of wraparound sleeves, creating a premium packaging solution that elevates product presentation while ensuring superior protection during shipping and retail display. This hybrid format features an inner tray or box that holds the soap securely, covered by an outer sleeve that slides over the structure for complete brand coverage and enhanced visual appeal. Starting with 100-unit minimum orders, box sleeve packaging offers artisan soap makers and premium brands a professional solution competing with high-end retail products.

Hybrid Structure Benefits and Applications

Box sleeve packaging addresses limitations of both simple wraps and full boxes by combining structural protection with expansive branding surfaces. Unlike the belly band alternative that offers minimal coverage, box sleeves provide complete surface area for comprehensive brand storytelling and regulatory information. The inner box component provides crush resistance and product security, while the outer sleeve delivers 360-degree design coverage without compromising structural integrity.

This format particularly suits premium product lines where packaging quality directly influences perceived value and purchase decisions. Gift collections, luxury soap sets, and specialty formulations benefit from the substantial feel and professional presentation that box sleeve packaging delivers.

Primary packaging advantages include:

- Superior protection through dual-layer construction

- Complete surface coverage for maximum branding impact

- Premium tactile experience justifying higher price points

- Structural stability during shipping and retail handling

- Easy opening mechanism enhancing customer experience

- Reusable inner box extending packaging utility

Implementation across business models:

- Luxury soap brands emphasizing quality and craftsmanship

- Gift collections requiring premium presentation standards

- Spa and wellness products positioning as high-end offerings

- Specialty soaps with unique shapes requiring custom support

- Wholesale accounts demanding maximum protection and professional appearance

| Business Type | Box Material | Sleeve Material | Primary Benefit |

|---|---|---|---|

| Luxury Brands | Rigid board | 250-300 GSM | Premium positioning |

| Gift Collections | Corrugated | 220-280 GSM | Presentation quality |

| Spa Products | Rigid board | 250-300 GSM | Sophisticated aesthetic |

| Wholesale | Corrugated | 200-250 GSM | Protection + branding |

Material Construction for Box Components

High-quality box packaging sleeves require careful material selection for both the inner structure and outer sleeve components. Each element serves distinct functional and aesthetic purposes, requiring specific optimization based on the product’s unique requirements and overall brand positioning.

Chipboard construction (300-500 GSM) offers economical structural support for products sold primarily in controlled retail environments. This material provides adequate crush resistance for stacked shelf display while keeping production costs manageable for volume orders.

- 300-400 GSM chipboard: Basic structural support, cost-effective

- 400-500 GSM chipboard: Enhanced rigidity, standard retail protection

- Rigid board (1-2mm): Premium feel, maximum protection

- Corrugated board: Superior cushioning, shipping-optimized

- Specialty boards: Textured surfaces, unique aesthetic options

Inner box construction considerations:

- Assess distribution channel handling intensity

- Determine if box serves post-purchase storage function

- Evaluate cost-benefit of premium materials

- Consider manufacturing complexity for custom shapes

- Test structural integrity with actual soap weight and dimensions

| Inner Box Material | Thickness | Protection Level | Cost Factor | Best Application |

|---|---|---|---|---|

| 300-400 GSM Chipboard | 0.30-0.40mm | Moderate | Low | Retail only |

| 400-500 GSM Chipboard | 0.40-0.50mm | Good | Moderate | Standard distribution |

| Rigid Board | 1-2mm | Excellent | High | Premium positioning |

| Corrugated | 3-5mm | Superior | Moderate | E-commerce shipping |

Material Selection for Inner Structure

The printed sleeve upgrade often incorporates rigid board construction for luxury presentations, while corrugated options suit e-commerce fulfillment where shipping protection matters most. By selecting the appropriate material base, brands can ensure their product remains fully protected during transit while still delivering a high-end visual impact to the end consumer.

Sleeve materials must balance printability, structural stability during application, and resistance to handling wear. Heavier cardstock weights (200-300 GSM) maintain shape while sliding over inner boxes without tearing or buckling during assembly and customer use.

Outer sleeve material benefits:

- 200-220 GSM: Adequate for small boxes, cost-efficient

- 220-250 GSM: Standard choice for most applications, versatile

- 250-300 GSM: Premium feel, enhanced durability

- Coated stocks: Superior print reproduction, moisture resistance

- Uncoated options: Natural aesthetic, eco-friendly positioning

Sleeve material selection process:

- Match weight to inner box dimensions and rigidity

- Ensure smooth sliding action without excessive looseness

- Select finish supporting intended printing techniques

- Consider how material handles repeated sliding during customer use

- Test samples with actual box components for fit verification

| Sleeve Material | Rigidity | Print Quality | Sliding Ease | Durability |

|---|---|---|---|---|

| 200-220 GSM | Moderate | Good | Very Easy | Moderate |

| 220-250 GSM | Good | Excellent | Easy | Good |

| 250-300 GSM | High | Superior | Moderate | Excellent |

Sleeve Weight and Performance Balance

The luxury wrap finish specifies 250-300 GSM sleeve materials paired with rigid board inner boxes to create substantial unboxing experiences that justify premium pricing structures. This combination provides a heavy, high-quality feel that communicates luxury while ensuring internal contents remain securely protected during transit.

Box sleeve packaging accommodates various structural configurations supporting different product dimensions, opening mechanisms, and brand aesthetic requirements. Configuration choices impact both functionality and production economics.

Standard Box Styles and Sleeve Formats

Tray-style boxes with separate lids work well for products customers may want to store in original packaging after purchase. The sleeve slides over the assembled tray, securing the lid while providing complete branding coverage. This configuration suits gift products and luxury collections where reusability matters.

Tuck-end boxes offer integrated closure mechanisms that self-lock when assembled, eliminating separate lid components. Sleeves slide over these structures providing additional security and complete brand coverage. This format works well for products moving through distribution channels requiring tamper-evidence.

- Tray with lid: Reusable structure, premium feel, higher production cost

- Tuck-end box: Integrated closure, efficient assembly, cost-effective

- Magnetic closure: Luxury positioning, highest cost, memorable unboxing

- Window cut-outs: Product visibility through sleeve and box

- Multi-compartment: Sets or variety packs, complex construction

Configuration selection factors:

- Customer expectation for post-purchase storage functionality

- Assembly complexity during packaging operations

- Distribution channel security and tamper-evidence requirements

- Budget allocation for structural components

- Brand positioning and target price point

| Box Style | Closure Type | Assembly Complexity | Cost Level | Best For |

|---|---|---|---|---|

| Tray + Lid | Separate pieces | Moderate | Moderate-High | Gift products |

| Tuck-End | Integrated tabs | Low | Low-Moderate | Standard retail |

| Magnetic | Embedded magnets | Low | High | Luxury lines |

| Window Cut | Varies | Moderate | Moderate-High | Visual products |

Configuration Complexity and Production

The kraft box wrap option utilizes tray-style construction with natural brown inner boxes complementing uncoated kraft sleeves, creating cohesive eco-friendly presentation throughout the package. This dual-layered approach reinforces sustainable brand values while providing extra protection for artisanal products.

Sleeve removal ease impacts customer experience and influences perceived quality. Tight-fitting sleeves suggest precision manufacturing but may frustrate customers, while loose sleeves appear lower quality despite easier handling.

Opening mechanism options include:

- Standard slide: Friction fit, no special features required

- Pull tab: Designated grip area, assists removal

- Thumb notch: Die-cut opening for finger access

- Perforated tear: One-time removal, tamper-evident

- No-resistance: Deliberately loose for easy access

Mechanism selection considerations:

- Balance security during shipping with customer convenience

- Consider whether sleeve removal is permanent or temporary

- Evaluate how mechanism reflects brand character

- Assess production cost implications of special features

- Test actual customer interaction during prototyping

| Opening Mechanism | Removal Ease | Production Cost | Reusability | Security Level |

|---|---|---|---|---|

| Standard Slide | Moderate | Base | Yes | Good |

| Pull Tab | Easy | +10-15% | Yes | Moderate |

| Thumb Notch | Easy | +15-20% | Yes | Moderate |

| Perforated Tear | Very Easy | +20-25% | No | High |

Mechanism Design for User Experience

Understanding style variations helps brands select opening mechanisms aligning with target customer preferences and product positioning strategies. This thoughtful selection ensures that the unboxing experience mirrors the product quality while effectively meeting specific consumer expectations and market demands.

Box sleeve packaging offers extensive printing and finishing opportunities across both inner box and outer sleeve components. Coordinated design between elements creates cohesive brand experience from first impression through complete unboxing.

Multi-Surface Design Coordination

Strategic design coordination between visible surfaces maximizes brand impact while guiding customer attention through unboxing sequence. The outer sleeve delivers first impression, while inner box surfaces reveal progressive messaging as customers remove the sleeve and open the package.

Outer sleeve printing typically features full-color graphics, product photography, and primary brand messaging. Inner box surfaces can display complementary designs, usage instructions, ingredient details, or brand storytelling elements that reward customer engagement.

- Outer sleeve: Primary branding, product imagery, key information

- Inner box exterior: Complementary design, secondary messaging

- Inner box interior: Usage instructions, brand story, ingredient details

- Coordinated color palettes: Visual cohesion across all surfaces

- Progressive information: Layered messaging revealed through unboxing

Design coordination strategy includes:

- Establish visual hierarchy across multiple surfaces

- Coordinate color palettes between inner and outer elements

- Plan information flow matching natural unboxing sequence

- Consider how designs interact when sleeve is partially removed

- Balance comprehensive branding with visual restraint

| Surface | Design Priority | Information Type | Print Complexity |

|---|---|---|---|

| Sleeve Exterior | Highest | Primary branding | Complex |

| Box Exterior | Moderate | Secondary messaging | Moderate |

| Box Interior | Lower | Detailed information | Simple-Moderate |

Coordinated Design Across Package Elements

The handmade soap band demonstrates how minimal exterior design can be elevated through thoughtful box sleeve construction, transforming simple bands into comprehensive packaging systems. This strategic structural approach ensures that even the most basic wraps provide robust protection and high-end visual appeal.

Box sleeve packaging justifies investment in premium finishing techniques that create memorable tactile experiences and reinforce luxury positioning. Multiple finishing methods can be combined across different package components for maximum differentiation.

Advanced finishing options include:

- Spot UV: Selective gloss highlights on matte backgrounds

- Soft touch coating: Velvet texture on sleeves, premium feel

- Metallic foils: Gold, silver, copper accents on branding elements

- Embossing: Dimensional details on logos or patterns

- Debossing: Subtle impressions creating sophisticated detail

- Combination techniques: Layered finishes for maximum impact

Finishing selection considerations:

- Determine which surfaces benefit most from premium treatments

- Calculate cost-benefit ratio against retail price positioning

- Consider how finishes photograph for e-commerce presentation

- Evaluate tactile impact during in-store customer interaction

- Test finish durability through shipping and handling simulation

| Finishing Type | Application Surface | Visual Impact | Production Minimum | Enhancement Category |

| Spot UV | Sleeve exterior | High contrast gloss | 100 units | Visual/Reflective |

| Soft Touch | Sleeve exterior | Luxury tactile feel | 100 units | Sensory/Matte |

| Metallic Foil | Sleeve/box | Premium metallic shine | 100 units | High-End Branding |

| Embossing | Sleeve exterior | Dimensional texture | 100 units | Structural/Tactile |

| Aqueous Coating | Full surface | Protective satin finish | 100 units | Functional/Durability |

Workflow Management Across Components

The custom fit sleeve consideration becomes critical in box sleeve packaging, as both inner box and outer sleeve must maintain precise dimensional tolerances for proper fit and smooth operation.

Assembly approach impacts both production costs and shipping efficiency. Products can ship flat requiring customer or retailer assembly, partially assembled with sleeves separate, or fully assembled ready for immediate retail display.

Assembly configuration options:

- Flat pack: Lowest shipping cost, requires assembly, volume efficient

- Partially assembled: Box assembled, sleeve separate, moderate efficiency

- Fully assembled: Ready for display, highest shipping volume, premium positioning

- Automated assembly: High volume production, equipment investment required

- Manual assembly: Flexible for lower volumes, labor intensive

| Assembly Method | Shipping Efficiency | Labor Cost | Customer Experience | Best For |

|---|---|---|---|---|

| Flat Pack | Highest | Minimal | Requires assembly | High volume |

| Partial Assembly | Good | Low | Some assembly | Moderate volume |

| Full Assembly | Lower | Moderate | Ready to display | Premium positioninFg |

Market Positioning and Performance

Understanding market solutions helps businesses select assembly methods matching distribution channel requirements and customer expectations. This alignment ensures that the structural design facilitates efficient shipping while providing a seamless, high-quality unboxing experience for every end user.

Box sleeve packaging commands premium pricing reflecting enhanced production complexity and superior customer experience. This format suits brands emphasizing quality, craftsmanship, and luxury positioning where packaging quality directly influences purchase decisions.

Pricing Structure and Value Justification

Production costs for box sleeve packaging typically run 40-60% higher than simple sleeves due to dual-component manufacturing and assembly requirements. However, this investment often enables 50-100% higher retail pricing through enhanced perceived value.

Cost component breakdown includes:

- Inner box materials and manufacturing: 50-60% of total cost

- Outer sleeve production: 30-35% of total cost

- Assembly labor: 10-15% of total cost

- Design and tooling: Amortized across order volume

Volume pricing structure:

- 100-499 units: Testing quantities, higher per-unit cost

- 500-999 units: Improved pricing, specialty finish access

- 1,000-2,499 units: Standard production efficiency

- 2,500+ units: Optimal pricing, full customization options

| Order Quantity | Per-Unit Cost Tier | Packaging Complexity | Profitability Multiple | Market Positioning |

| 100-499 | Standard Tier | Premium vs Simple | 3-4x production cost | Emerging Brand |

| 500-999 | Mid-Level Tier | Premium vs Simple | 3-4x production cost | Local Presence |

| 1,000-2,499 | Professional Tier | Premium vs Simple | 3-4x production cost | Regional Expansion |

| 2,500+ | Enterprise Tier | Premium vs Simple | 3-4x production cost | National Distribution |

Cost Analysis and Retail Positioning

Despite higher production investment, box sleeve packaging demonstrates strong return on investment for premium brands through justified retail pricing and reduced damage rates during distribution.

Performance indicators across channels:

- Gift market: 35-45% higher conversion rates than simple wraps

- Premium retail: Enhanced shelf presence attracting quality-focused customers

- E-commerce: Reduced damage claims through superior protection

- Wholesale: Increased buyer confidence in product presentation

Market Performance Across Sales Channels

Box sleeve packaging particularly excels in gift markets and premium retail environments where presentation quality influences purchasing decisions and justifies higher price points that support enhanced packaging investment.