Description

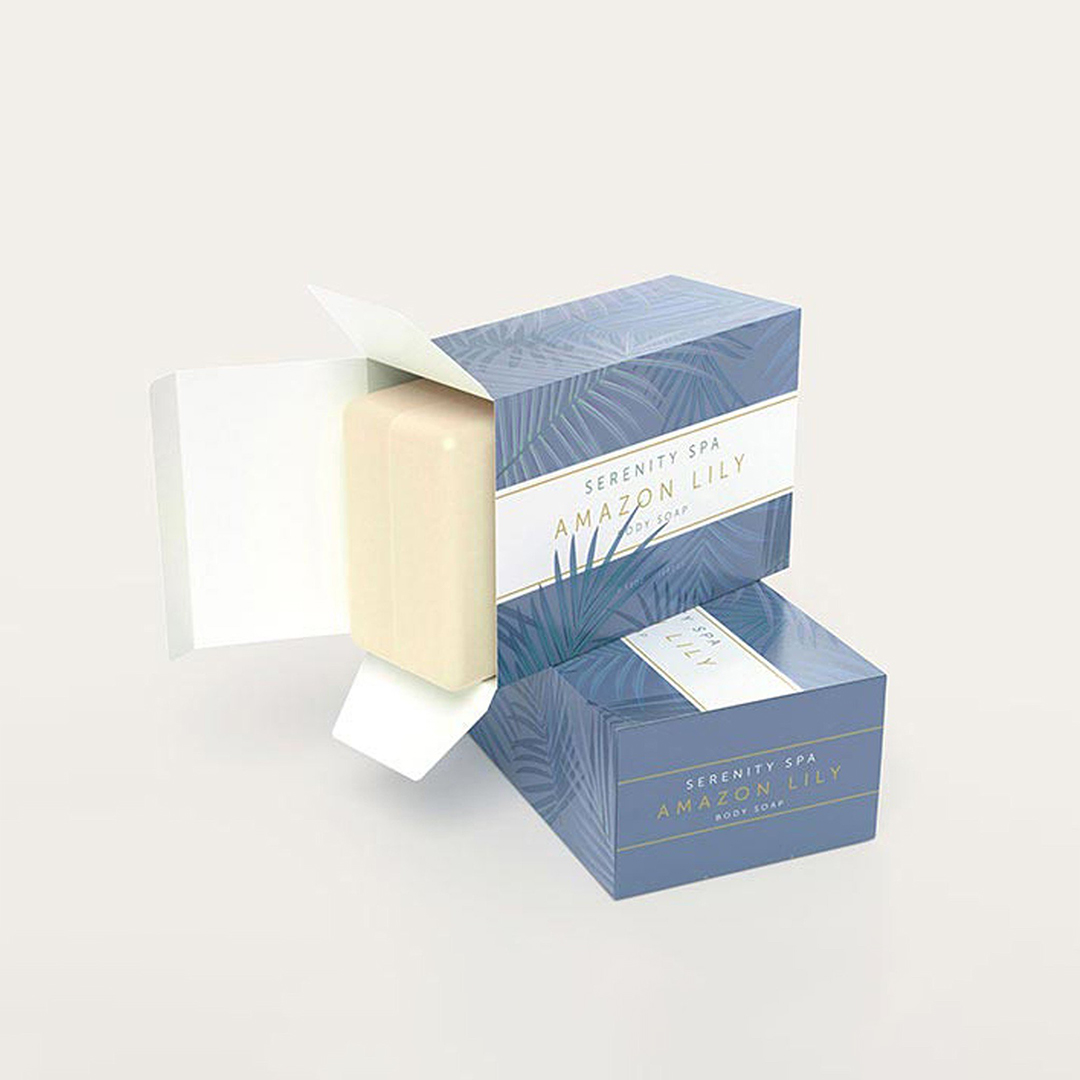

Custom Size Soap Sleeves for Unique Products

Artisan soap businesses benefit from custom sized sleeves matching their unique product dimensions exactly. Oversized bars, thin guest soaps, round shapes, and specialty geometries all require packaging solutions standard options cannot provide. Utilizing printed sleeve styles allows businesses to combine dimensional precision with graphic customization creating truly unique packaging solutions.

Custom size soap sleeves solve the challenge of packaging irregularly shaped or non-standard soap bars. Handmade soap makers create products in various dimensions that standard packaging cannot accommodate. Our custom sizing service ensures perfect fit regardless of soap bar shape, thickness, or length. This precision prevents movement during shipping while maintaining professional presentation throughout customer experience.

Understanding Dimensional Customization Benefits

Custom sizing accommodates production variations common in handmade soap making. Bar dimensions fluctuate slightly between batches due to manual cutting and natural settling processes. Considering embossed options requires similar precision ensuring embossed details align properly with soap dimensions without distortion or misalignment.

The dimensional customization process begins with precise soap measurements. Width, height, and depth specifications ensure sleeves fit properly without excessive looseness or uncomfortable tightness. Proper sizing creates professional appearance while protecting soap during handling and distribution.

Measuring Soap Bars Accurately

Accurate measurements require accounting for soap bar irregularities. Handmade soaps rarely achieve perfectly uniform dimensions. Measuring widest points ensures sleeves accommodate full bar size. Adding tolerance margins prevents fit issues from minor production variations.

Measurement best practices include:

- Measure multiple bars from same batch noting variations

- Record widest dimensions for width, height, depth

- Add 2-3mm tolerance for comfortable fit

- Account for any protruding decorative elements

- Consider soap shape irregularities from hand-cutting

- Test samples before committing to large orders

Different soap types require different measurement approaches. Cold process soaps may continue shrinking slightly after cutting. Hot process soaps maintain more stable dimensions. Melt and pour creations hold precise shapes. Understanding your production method helps determine appropriate tolerances.

| Soap Type | Typical Variation | Recommended Tolerance | Measurement Timing |

|---|---|---|---|

| Cold Process | ±3-5mm | +4mm | 4-6 weeks after cutting |

| Hot Process | ±2-3mm | +3mm | 2-3 days after cutting |

| Melt & Pour | ±1mm | +2mm | Immediately after unmolding |

| Hand-Milled | ±4-6mm | +5mm | 1 week after pressing |

Custom Sizing for Unique and Irregular Soap Bars

Custom sizing extends beyond rectangular bars to unusual shapes. Round soaps, oval designs, hexagonal creations, and asymmetric art pieces all require custom sleeve configurations. Evaluating kraft material choice demonstrates natural aesthetic versatility adapting to various soap shapes while maintaining organic appeal.

Curved soaps need sleeves accounting for three-dimensional geometry. Flat measurements don’t capture full circumference requirements. Template creation using actual soap bars ensures accurate sizing for complex shapes. Digital measurement tools provide precision impossible with traditional rulers.

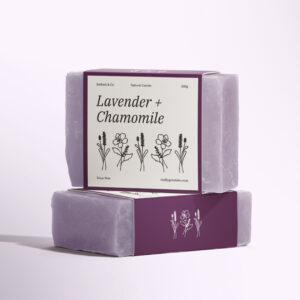

Material Selection for Custom Dimensions

Material choice affects how well custom-sized sleeves perform. Heavier cardstock maintains shape with large custom dimensions. Lighter materials work better for small specialty soaps. The paper wrap option offers flexibility suiting various sizing requirements without excessive rigidity.

Material thickness influences fit tolerances. Thicker materials require larger tolerance margins accounting for material bulk during sleeve formation. Thinner stocks allow tighter tolerances creating snug fits without binding. Understanding these relationships helps optimize custom sizing specifications.

Weight and Thickness Options

Different material weights suit varied custom sizing applications. Lightweight options (80-100 GSM) work well for small guest soaps or sample sizes. Standard weights (120-150 GSM) accommodate most handmade bar dimensions. Heavy-duty materials (180-250 GSM) support oversized specialty soaps.

Material weight recommendations:

- Guest soaps (under 2 oz): 80-100 GSM paper

- Standard bars (3-5 oz): 120-150 GSM cardstock

- Large bars (6-10 oz): 150-180 GSM cardstock

- Oversized specialty (10+ oz): 200-250 GSM heavy cardstock

- Delicate decorative soaps: 100-120 GSM gentle wrap

- Dense utility bars: 180-220 GSM durable stock

Material flexibility becomes important with unusual soap shapes. Curved or angular products need materials conforming to three-dimensional surfaces without creasing or buckling. Testing material drape characteristics with actual soap samples prevents production issues.

Design Adaptation for Custom Sizes

Design layouts must adapt to custom dimensions maintaining visual balance. Standard design templates don’t translate directly to unusual sizes. Graphics, text placement, and branding elements require adjustment ensuring professional appearance regardless of sleeve dimensions.

Proportional scaling maintains design integrity across size variations. Logo sizing adjusts relative to overall sleeve area. Text remains legible without appearing cramped or lost. The belly band style demonstrates how minimal design adapts effectively to varied dimensions through strategic placement.

Layout Principles

Design principles vary based on sleeve dimensions. Tall narrow sleeves require vertical design orientation. Wide shallow sleeves benefit from horizontal layouts. Square formats allow centered symmetrical compositions. Each proportion demands unique design approach.

Design considerations include:

- Logo placement adapting to available space

- Text sizing maintaining readability across dimensions

- Graphic element scaling preserving visual impact

- Color balance across varied surface areas

- Information hierarchy working in any format

- Brand consistency despite dimensional variations

Unusual shapes create unique design opportunities. Hexagonal sleeves suggest honeycomb patterns. Round wraps enable continuous design flow. Asymmetric shapes allow creative graphic exploration impossible with standard rectangles. Custom sizing unlocks design possibilities enhancing brand differentiation.

| Sleeve Shape | Design Approach | Visual Opportunities | Technical Challenges |

|---|---|---|---|

| Rectangular | Standard grid layouts | Familiar, versatile | Common, less distinctive |

| Square | Centered symmetry | Balanced, modern | Limited vertical space |

| Tall Narrow | Vertical orientation | Elegant, distinctive | Text sizing constraints |

| Wide Shallow | Horizontal flow | Panoramic graphics | Information density |

| Circular | Continuous design | Unique, memorable | Text orientation complexity |

| Irregular | Creative freedom | Maximum uniqueness | Production complexity |

Production Process for Custom Sizing

Digital die-cutting technology enables custom sizes without traditional metal die expenses. This approach suits smaller orders or businesses testing multiple size options before committing to large inventories. Exploring luxury packaging choice often utilizes custom sizing ensuring premium products receive perfectly fitted presentation.

Custom size production requires specialized die creation matching exact specifications. Dies cut and score material precisely forming sleeves fitting specific soap dimensions. This tooling investment amortizes across order quantities making custom sizing economical at volume.

Order Minimums and Quantities

Custom sizing minimums typically start at 100-250 units depending on size complexity and production method. Simple rectangular customs may accept lower minimums. Highly unusual shapes require larger quantities justifying die creation costs.

Volume pricing structure:

- 100-249 units: Higher per-unit cost, suitable for testing

- 250-499 units: Moderate pricing, good for initial launches

- 500-999 units: Standard pricing, regular production volumes

- 1,000-2,499 units: Volume discounts, established products

- 2,500+ units: Optimal pricing, wholesale distribution

Production timelines extend slightly for custom sizes versus standard options. Die creation adds 2-3 days to standard production schedules. First-time orders require more lead time than reorders using existing dies. Planning ahead prevents delays affecting product launch timelines.

Multiple Size Coordination

Soap makers offering product lines in varied sizes benefit from coordinated custom sleeve families. Maintaining consistent design across different dimensions creates unified brand presentation. Size variations serve different market segments while preserving brand recognition.

Coordinated sizing strategies include proportional scaling maintaining design relationships across sizes. Color coding differentiates sizes while maintaining visual family. Consistent graphic elements tie varied dimensions together creating cohesive product range.

Professional Product Line Packaging Application

Understanding all printing options helps create size-coordinated families maintaining consistent quality across dimensional variations. Print techniques must adapt to different surface areas without compromising reproduction quality or color accuracy.

Different soap sizes serve specific market purposes. Travel sizes use small custom sleeves. Standard bars utilize medium sizing. Gift sizes require larger custom dimensions. Each size targets distinct customer needs while representing same brand identity.

Size-based market segmentation:

- Sample/travel size: Customer acquisition, testing

- Standard size: Regular daily use, core sales

- Large/value size: Loyal customers, cost savings

- Gift size: Special occasions, premium pricing

- Bulk/wholesale: Commercial accounts, volume sales

Material Choices Across Custom Sizes

Reviewing the all materials section demonstrates material versatility across different soap packaging applications. Custom sizing combines with material selection creating packaging matching both dimensional requirements and brand aesthetic preferences.

Different materials suit varied custom sizing applications. Natural kraft works well for organic soap lines regardless of size. White cardstock provides clean backgrounds for colorful designs. Specialty papers create distinctive textures enhancing premium positioning.

Sustainability Considerations

Custom sizing impacts material efficiency. Unusual dimensions may generate more waste during production compared to standard sizes optimized for material sheet layouts. However, precise fitting reduces excess packaging material shipping to customers.

Environmental optimization strategies:

- Design sizes utilizing full material sheets efficiently

- Minimize complex die-cut patterns reducing scrap

- Choose recyclable materials supporting circular economy

- Consider material weight reducing shipping impact

- Evaluate reusable packaging options for premium lines

- Calculate total lifecycle environmental footprint

Sustainable practices balance custom sizing benefits against material efficiency. Working with manufacturers optimizing layouts maximizes material utilization while achieving desired custom dimensions.

Premium Specialty Shape Packaging Capabilities

Complex shapes require careful engineering ensuring structural integrity. Curved sleeves need strategic scoring enabling proper folding without buckling. Asymmetric designs require balanced construction preventing warping. Selecting all style categories showcases diverse shape options possible through custom manufacturing.

Beyond simple rectangular variations, true custom shapes accommodate unique soap artistry. Oval soaps, circular bars, hexagonal creations, and free-form art pieces all require specialized sleeve configurations. These specialty shapes command premium pricing reflecting die creation complexity.

Engineering Complex Shapes

Unusual shapes present engineering challenges requiring expertise. Three-dimensional soap forms need sleeves accounting for full geometry. Surface area calculations ensure adequate material coverage. Closure mechanisms must work with non-standard configurations.

Shape complexity factors:

- Number of sides or curves in design

- Symmetry versus asymmetry affecting die layout

- Closure method compatibility with shape

- Structural stability during shipping and handling

- Assembly difficulty for hand-application operations

- Material waste generation from complex cutting

Testing prototypes with actual soap bars validates engineering before full production. Physical samples reveal issues digital mockups cannot anticipate. Iterative refinement achieves optimal results balancing aesthetics, functionality, and production efficiency.

Versatile Market Applications for Box Packaging

Considering market focused sleeves addresses specific industry needs through dimensional customization. Medical soaps for healthcare facilities, industrial hand cleaners for workshops, and specialty formulations for unique applications all benefit from custom sizing matching their specific use cases.

Custom sizing serves diverse market segments with specific dimensional requirements. Luxury spa products often feature oversized bars requiring custom large sleeves. Hotel amenity soaps need small custom dimensions. Wedding favors utilize unique shapes matching event themes.

Industry-Specific Requirements

Different industries require specific sizing supporting their applications. Food service soaps need compact dimensions fitting dispensers. Automotive workshops require large heavy-duty bars with substantial sleeves. Each market segment presents unique sizing requirements.

Industry sizing patterns:

- Hospitality: Small guest sizes, premium presentation

- Healthcare: Medical standard dimensions, hygiene emphasis

- Industrial: Oversized heavy-duty bars, durability focus

- Beauty/spa: Varied artistic shapes, luxury appearance

- Gift market: Unique shapes, memorable presentation

- Private label: Custom sizes matching brand requirements

Understanding market needs helps optimize custom sizing serving specific customer segments effectively. Dimensional precision combined with appropriate design creates packaging supporting successful market positioning.

Technical Production Considerations

Custom size production requires precise technical execution. Die accuracy determines sleeve fit quality. Scoring depth affects folding ease. Material grain direction influences structural integrity. These technical factors impact final product performance.

Manufacturing expertise ensures technical requirements translate into functional packaging. Tolerance specifications account for material characteristics. Production processes optimize efficiency without compromising quality. Technical consultation helps businesses navigate complex custom sizing decisions.

Quality Control Measures

Custom sizing demands rigorous quality control preventing fit issues. Sample production validates dimensions before full runs. Ongoing inspection catches variations during production. Final testing confirms sleeves fit actual soap bars properly.

Quality assurance steps include:

- Pre-production sample approval with actual soap

- Die accuracy verification against specifications

- Material thickness confirmation throughout production

- Fit testing with multiple soap samples

- Visual inspection for scoring and cutting quality

- Final assembly testing confirming ease of use

Comprehensive quality control ensures custom sized sleeves perform as expected throughout their intended use supporting brand reputation and customer satisfaction.

Starting Your Custom Size Project

Beginning custom size projects requires clear communication of dimensional requirements and design preferences. Providing physical soap samples enables accurate measurement and prototype development. Digital specifications supplement physical samples ensuring precise manufacturing.

Customized sleeve options through manufacturer partnerships streamlines custom sizing processes. Experienced packaging partners guide material selection, design adaptation, and production optimization. This collaboration ensures successful outcomes matching vision with practical manufacturing realities.

Working relationships with custom packaging specialists provide ongoing support through product development and market evolution. Reordering simplifies through saved dies and specifications. Design refinements happen efficiently building on established baselines. Long-term partnerships support business growth through scalable custom packaging solutions.

Design Flexibility Advantages

Custom sizing enables design approaches impossible with standard dimensions. Unusual aspect ratios create distinctive shelf presence. Unique shapes reinforce brand identity through memorable packaging silhouettes. Dimensional customization becomes branding opportunity.

Creative freedom extends to closure mechanisms, window placements, and structural features. Custom sizes accommodate innovative design elements enhancing functionality and visual appeal. This flexibility supports brand differentiation in competitive markets.

Innovative Structural Features

Custom dimensions enable structural innovations enhancing user experience. Resealable closures adapt to any size. Window placements optimize product visibility regardless of dimensions. Hanging holes position appropriately for varied shapes.

Structural customization options:

- Custom window sizes and placements

- Adapted closure mechanisms for unique shapes

- Optimized hanging features for display

- Specialized perforation placement

- Custom embossing or debossing areas

- Unique opening mechanisms

Structural innovation combined with dimensional customization creates packaging solutions addressing specific customer needs while supporting brand objectives effectively.