Description

Soap Belly Bands – Minimalist Wrap Solution for Artisan Soap Presentation

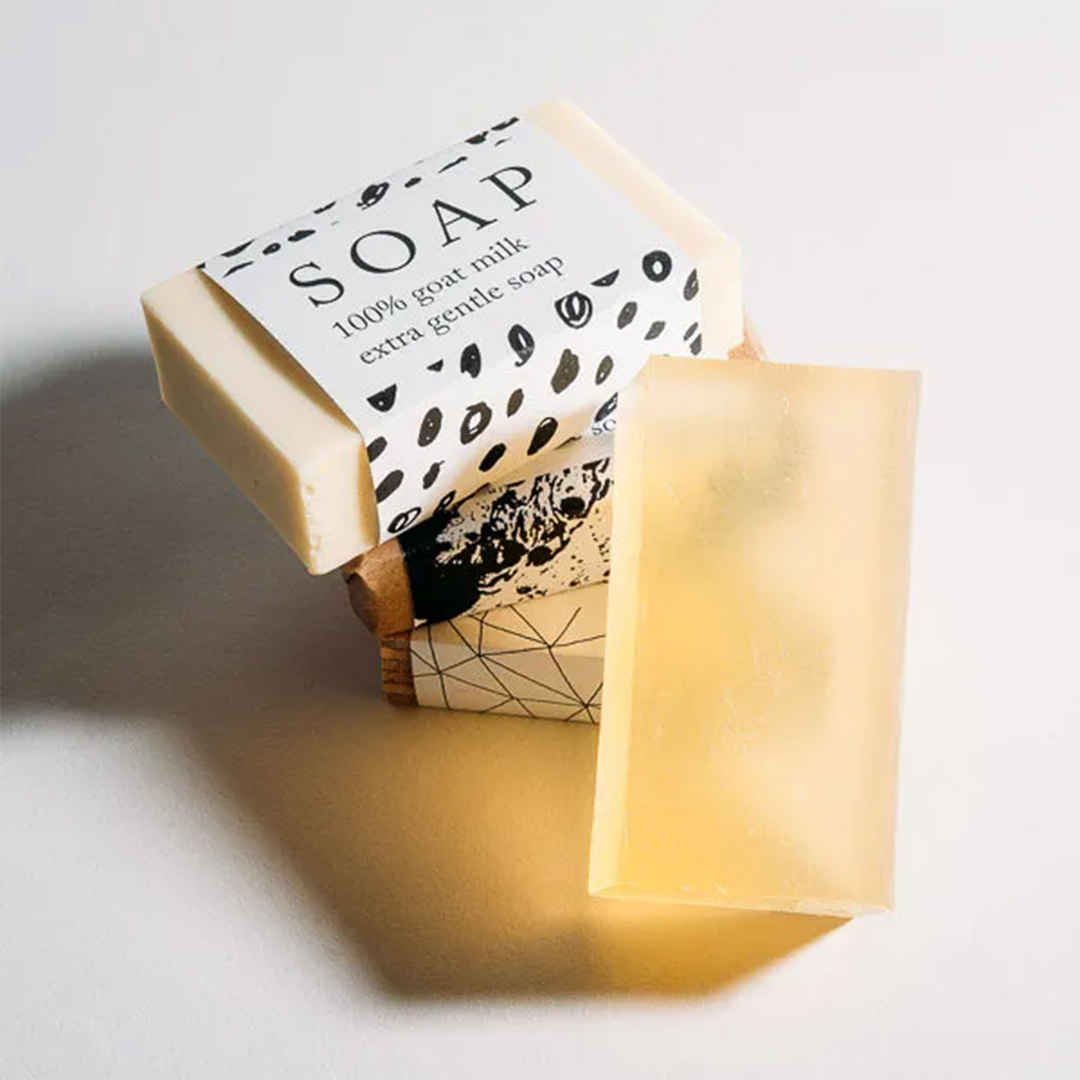

Soap belly bands represent a minimalist packaging approach that wraps around the center of soap bars, leaving the top and bottom exposed. This partial coverage design allows customers to see and touch the actual product while maintaining brand presence and protective functionality. Starting with just 100 unit minimum orders, belly bands offer accessible entry for small businesses and craft producers without significant capital investment.

Core Design Philosophy and Applications

The belly band format aligns with contemporary packaging trends favoring transparency and sustainability. Unlike the paper based alternative that provides full coverage, belly bands use significantly less material while creating an elegant, understated presentation that showcases soap craftsmanship.

Primary advantages include:

- Minimal material usage reduces production costs by 40-60%

- Showcases soap colors, textures and natural ingredients

- Quick manual application without specialized equipment

- Customers can smell and assess product before purchase

- Professional branding without overwhelming handmade aesthetics

- Flexible sizing accommodates various bar dimensions

Implementation by business type:

- Premium artisan brands highlighting soap quality and ingredients

- Eco-conscious companies demonstrating genuine waste reduction

- Farmers market vendors enabling sensory product sampling

- Spa and wellness products emphasizing therapeutic formulations

- Gift collections requiring elegant minimalist presentation

| Business Type | Recommended Width | Material Weight | Primary Benefit |

|---|---|---|---|

| Artisan Soap Makers | 1.5-2.5 inches | 150-200 GSM | Product visibility |

| Luxury Brands | 2.5-3 inches | 250-300 GSM | Premium aesthetics |

| Eco-Focused | 1-1.5 inches | 80-120 GSM | Material reduction |

| Wholesale Suppliers | 1.5-2 inches | 150-200 GSM | Cost efficiency |

Blank Sleeves For Protection And Custom Labels

The exposed soap format allows natural colors and embedded ingredients to become visual marketing elements. This approach particularly resonates with customers seeking authentic handmade products. For soaps with less distinctive appearance, the blank sleeve choice offers an alternative maintaining protection while allowing post production customization.

Material Construction and Weight Selection

Material choice significantly impacts both functionality and customer perception of your soap products. Belly bands utilize various cardstock weights depending on desired rigidity, application method, and brand aesthetic requirements.

Lightweight and Medium Weight Options

Lightweight materials (80-120 GSM) offer maximum flexibility and cost efficiency for high-volume production. Medium weight cardstock (150-200 GSM) represents the industry standard, balancing structural integrity with application ease while maintaining position during handling and shipping.

Material selection benefits:

- 80-120 GSM: Flexible wrapping, cost-effective, easy manual application

- 150-200 GSM: Professional appearance, maintains positioning, supports basic finishing

- Balance between flexibility and structural stability for retail environments

- Standard choice accommodates most printing and finishing techniques

- Adequate rigidity without application difficulty in production workflow

Weight evaluation process:

- Request samples in your intended design and finish specifications

- Test application on actual soap bars from current production

- Simulate retail handling and typical customer interaction patterns

- Assess performance in shipping and storage conditions

- Evaluate cost-effectiveness against projected order volumes

- Compare visual and tactile impact versus lighter alternatives

| Weight Range | Flexibility | Print Quality | Cost Level | Best Application |

|---|---|---|---|---|

| 80-120 GSM | Very High | Good | Lowest | Events, high-volume |

| 150-200 GSM | Moderate | Excellent | Standard | General retail |

| 250-300 GSM | Low | Superior | Premium | Luxury positioning |

Medium Weight Stocks For Printing And Band Fit

The custom size band option becomes particularly important with medium weight materials, as proper dimensions ensure bands stay positioned without adhesive failure or material buckling during handling.

Medium weight stocks accommodate most printing techniques and finishing options while maintaining reasonable production costs. This versatility makes them ideal for businesses testing different design approaches before committing to specific aesthetic directions.

Premium Heavyweight Construction

Heavyweight cardstock (250-300 GSM) creates substantial, premium feel that communicates quality and value. These materials support complex finishing techniques and maintain rigid positioning throughout product lifecycle from manufacturing through retail sale.

- Creates substantial tactile experience justifying premium pricing

- Stays positioned during handling and shipping stress

- Supports multiple finishing techniques on single band

- Best choice for luxury product line positioning

- Enhanced durability for wholesale distribution channels

- Superior print quality for detailed graphics and photography

Premium material applications:

- Upscale retail environments requiring luxury presentation

- Gift collections where packaging contributes to perceived value

- Spa products emphasizing quality and therapeutic benefits

- Limited edition releases justifying premium pricing

- Wholesale accounts with rigorous handling requirements

| Material Grade | Weight | Premium Features | Ideal For |

|---|---|---|---|

| Standard Heavy | 250 GSM | Embossing, spot UV | Upscale retail |

| Premium Heavy | 280 GSM | Multiple finishes | Luxury brands |

| Ultra Premium | 300 GSM | Foil + embossing | Gift collections |

Heavyweight materials work best when brand positioning emphasizes quality and craftsmanship. The increased material cost becomes negligible when distributed across higher retail prices that premium presentation supports.

Printing Methods and Finishing Options

Printing technique selection impacts both visual quality and production economics. Starting with our 100-unit minimum, businesses can access professional printing without prohibitive setup costs.

Digital and Offset Printing Comparison

Digital printing eliminates traditional plate costs, making small runs economically viable for testing designs or serving niche markets. Offset printing becomes cost-effective at 1,000+ units while delivering superior color consistency.

Digital printing advantages:

- No setup fees or plate costs required

- Quick turnaround time (7-10 business days)

- Full CMYK color capability without restrictions

- Easy design changes between production runs

- Cost-effective for testing multiple design variations

- Perfect for seasonal offerings and limited editions

Offset printing benefits:

- Exceptional print quality with fine detail reproduction

- Precise Pantone color matching for brand consistency

- Lower per-unit cost structure at volume orders

- Professional-grade finish quality exceeding digital capabilities

- Supports complex color gradients and photographic elements

| Printing Method | Best Quantity | Setup Cost | Per-Unit Cost | Color Matching |

|---|---|---|---|---|

| Digital | 100-999 | None | Higher | CMYK standard |

| Offset | 1,000+ | Moderate | Lower | Pantone precision |

Surface Finishing and Premium Techniques

Surface finishing techniques enhance both durability and aesthetic appeal while supporting specific brand positioning strategies. Basic coatings provide protective benefits while premium finishes create distinctive experiences.

- Matte coating: Subtle appearance, fingerprint resistant, suits organic brands

- Gloss coating: Vibrant colors, moisture resistant, contemporary aesthetic

- Satin finish: Balanced sheen, moderate protection, versatile appeal

- Uncoated: Natural texture, eco-friendly positioning, fully compostable

Premium finishing options:

- Spot UV highlighting specific design elements through contrast

- Soft touch coating creating memorable velvet-like texture

- Embossing adding dimensional brand details and tactile interest

- Metallic foils in gold, silver, copper, or rose gold

- Combination techniques for maximum differentiation impact

| Finish Type | Visual Impact | Minimum Quantity | Cost Addition |

|---|---|---|---|

| Spot UV | High contrast | 100 units | +$0.08-0.15 |

| Soft Touch | Subtle luxury | 100 units | +$0.12-0.20 |

| Foil Stamp | Metallic shine | 100 units | +$0.15-0.30 |

| Embossing | Dimensional | 100 units | +$0.10-0.18 |

Design Strategy and Content Organization

Premium finishes typically require 1,000+ units due to specialized equipment setup. The window cut out sleeve offers an alternative approach for brands wanting full coverage with strategic product visibility.

Creating effective belly band designs requires balancing information density with visual appeal in limited space. Strategic planning ensures essential details communicate clearly while maintaining attractive presentation supporting brand identity.

Information Hierarchy and Placement

Successful belly band design prioritizes information based on customer decision-making processes and regulatory requirements. Clear hierarchy ensures customers find relevant details quickly while maintaining visual cohesion that supports simple packaging ideas.

Information priority levels:

- Primary: Brand logo and product name identification

- Secondary: Key differentiators (organic, handmade, scent)

- Tertiary: Weight, size, or unit count information

- Quaternary: Ingredient highlights or benefit statements

- Regulatory: Warnings, allergens, contact information

Content placement strategy:

- Position logo on most visible face (front center)

- Place product name adjacent to logo for immediate identification

- Allocate side panels for ingredient and benefit information

- Reserve back panel for regulatory compliance details

- Integrate barcode placement without visual disruption

| Content Type | Recommended Position | Font Size Minimum | Space Allocation |

|---|---|---|---|

| Brand Logo | Front center | N/A | 25-35% |

| Product Name | Front with logo | 12-14 pt | 15-20% |

| Key Benefits | Front lower/sides | 8-10 pt | 15-20% |

| Ingredients | Side or back | 6-8 pt | 15-25% |

| Regulatory | Back panel | 6 pt minimum | 10-15% |

Research shows customers spend average 3-5 seconds evaluating handmade soap products, making immediate clarity essential for purchase decisions.

Visual Design Approaches

Different aesthetic strategies suit various brand positions and target demographics. Selecting appropriate visual approach requires understanding market segment preferences and competitive landscape dynamics.

- Minimalist: Clean typography, generous white space, single accent color

- Vintage: Classic typography, ornamental borders, muted palettes, heritage positioning

- Bold Graphic: High contrast, large typography, contemporary appeal to younger demographics

- Natural/Organic: Earth tones, botanical elements, sustainable messaging

Design style comparison:

| Design Style | Target Demographic | Brand Position | Printing Complexity |

|---|---|---|---|

| Minimalist | 25-45, urban | Premium, modern | Low |

| Vintage | 30-55, traditional | Heritage, craft | Moderate |

| Bold Graphic | 18-35, trend-focused | Contemporary | High |

| Natural/Organic | 25-50, eco-conscious | Sustainable | Low-Moderate |

Understanding Market Preferences Across Sales Channels

Understanding market preferences through different sales channels helps businesses build wrap designs that match what their customers actually notice, trust, and buy. By tracking feedback from online stores, in-person retailers, wholesale buyers, and social media, you can spot which colors, patterns, finishes, and messaging styles perform best for each audience

Production Timeline and Environmental Benefits

Understanding production workflow helps businesses plan inventory needs effectively. Our streamlined process minimizes lead time while maintaining quality standards across all order sizes starting from 100 units.

Order Processing and Timeline Management

Production begins once design approval and payment confirmation complete. Standard timeline runs 12-14 working days from approval through delivery, with rush options available for time-sensitive launches.

Production phase breakdown:

- Design approval: 1-2 business days

- Pre-production setup: 2-3 business days

- Printing execution: 2-4 business days (digital faster than offset)

- Finishing application: 1-2 business days standard coatings

- Die cutting and scoring: 1 business day

- Final inspection and packaging: 1 business day

- Shipping time: 3-7 days depending on location

Rush production options:

- 30% timeline reduction with 40% cost premium (8-10 days total)

- 40% timeline reduction with 50% cost premium (7-9 days total)

- 50% timeline reduction with 60% cost premium (6-7 days total)

| Timeline Type | Total Duration | Cost Premium | Best For |

|---|---|---|---|

| Standard | 12-14 days | None | Planned inventory |

| Moderate Rush | 8-10 days | +40% | Seasonal launches |

| Priority Rush | 6-7 days | +50% | Emergency needs |

Planning Orders Ahead With Sleeve Style Options

Planning inventory orders 4-6 weeks ahead provides buffer for unexpected delays while avoiding rush premium costs. The box style sleeve provides an alternative for products requiring more substantial structural protection with similar production timelines.

Environmental Impact and Sustainability

Belly bands represent one of the most environmentally responsible packaging options, using 40-60% less material than full sleeves while maintaining professional presentation standards appealing to eco-conscious consumers.

- Material reduction: 40-60% less paper than complete wrapping

- Energy savings: Proportional reduction in production consumption

- Shipping efficiency: Lower weight reduces transportation emissions

- Waste reduction: Decreased disposal volume and processing requirements

- Recycling compatibility: Simple composition works in standard programs

- Biodegradability: Decomposes within 2-4 months in proper conditions

End-of-life processing options:

- Uncoated paper: Recyclable, compostable, biodegradable (all pathways)

- Matte coated: Recyclable, limited composting capability (recycling preferred)

- Gloss coated: Recyclable, not compostable (recycling only)

- Foil stamped: Recyclable after processing separation (recycling only)

- Embossed: Recyclable, compostable, biodegradable (all pathways)

| Packaging Type | Material Usage | Energy Consumption | Carbon Footprint |

|---|---|---|---|

| Belly Band | Baseline | Baseline | Baseline |

| Full Paper Sleeve | +85-120% | +70-90% | +75-95% |

| Cardboard Sleeve | +100-150% | +90-120% | +95-125% |

| Rigid Box | +200-350% | +180-280% | +190-300% |

Material efficiency becomes increasingly important as environmental regulations tighten and consumer preferences shift toward sustainable packaging choices. Brands demonstrating genuine commitment to waste reduction gain competitive advantages in growing eco-conscious market segments while maintaining professional presentation supporting premium pricing strategies.