Description

Plastic Clear Soap Sleeves For Shelf Visibility

Plastic Clear Soap Sleeves help shoppers see the bar color, texture, and embedded botanicals without opening anything. For stores and online listings, clear packaging sleeves for soaps keep the product looking clean while still letting the soap do the selling. When the sleeve sits flat and the edges look neat, the bar appears more consistent in photos, on counters, and inside gift sets. This also supports quick packing when you handle many scent variants. Large plastic clear soap sleeves are often used when bars are thicker, layered, or wrapped with extra inserts.

Clear sleeves are also useful when buyers ask simple questions like “Will the soap stay clean in storage” or “Can I see the design before buying.” The window sleeve alternative works for brands that want a paper look with a viewing cutout, while fully clear sleeves keep the whole bar visible. If you sell at stalls or ship daily, clear sleeves reduce surface dust and keep labels from rubbing directly on the soap. The right fit prevents twisting and keeps corners from looking loose. This makes soap display sleeves clear and tidy during handling.

How Clear Sleeves Protect Bars During Shipping Safely

During packing and transit, bar edges can scuff when they rub against cartons, dividers, or other soaps. A protective waterproof wrap helps reduce moisture contact and keeps the sleeve surface cleaner when parcels move through different temperatures. This matters for handmade bars that can sweat slightly in humid weather. With a clean wrap, the soap stays presentable when customers open the box. It also helps reduce fingerprints on the bar surface during handling.

Clear sleeves can also be paired with branding elements without making the pack feel heavy. A belly band option can add scent names, ingredients, or batch details while keeping the soap visible from most angles. That combination answers user intent quickly because shoppers can see the bar and still read the key details. If you need barcode scanning, the band can carry the barcode while the sleeve keeps the bar protected. Keep the band snug but not tight, and keep folds away from the barcode zone so scanning stays smooth.

Key Benefits Buyers Notice With Clear Sleeves Today

- Bar design stays visible without opening packaging

- Surface stays cleaner during handling and storage

- Product photos look consistent across scent variants

- Wrapping speed improves for high volume packing

- Display looks tidy for shelves and market stalls

Steps To Choose Clear Wrap Size And Thickness Right

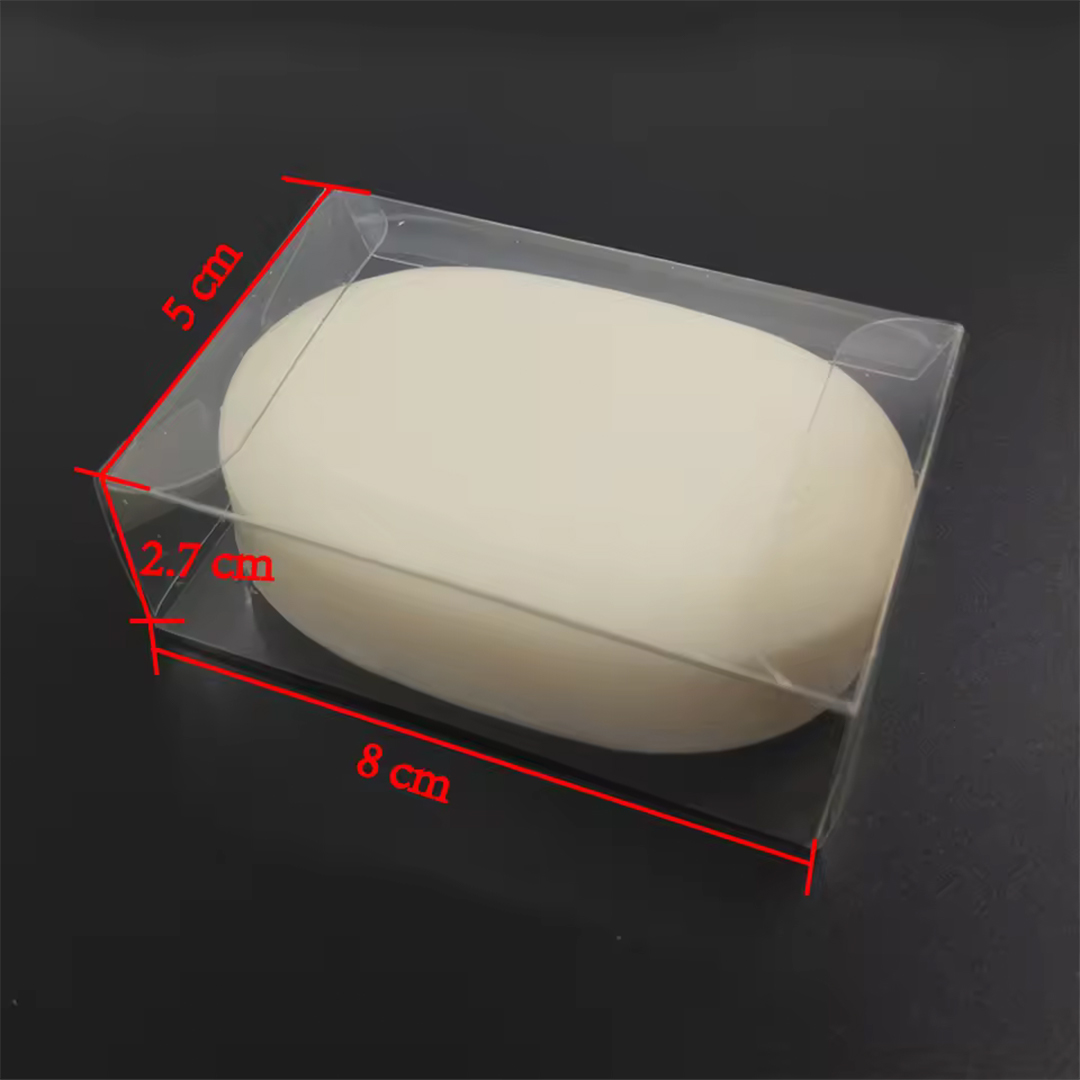

- Measure bar width, height, and depth with a small allowance

- Confirm the sleeve closes neatly without squeezing corners

- Pick thickness based on shipping distance and handling level

- Keep any label or band on a flat zone for readability

- Wrap test bars from different batches before final quantities

| Feature Focus | What It Supports | Size Tip | Handling Note | Best Use |

|---|---|---|---|---|

| Full Visibility | Shows bar color and texture | Leave slide-on space | Avoid over-tight wrap | Retail display |

| Clean Surface | Reduces dust contact | Match bar depth | Store sleeves flat | Daily packing |

| Moisture Control | Helps in humid shipping | Choose thicker film | Keep seals neat | Online orders |

| Label Space | Clear reading areas | Use flat zones | Avoid fold overlap | Barcodes |

| Tidy Finish | Neat edges and corners | Confirm fold room | Prevent twisting | Gift sets |

Clear Soap Sleeves For Handmade Soap Display Stalls

Clear soap sleeves for handmade soap help buyers see swirls, layers, and natural add-ins without touching the bar. A visible bar often sells faster because shoppers can compare color and texture at a glance. At market stalls, clear soap sleeves for market stalls also keep dust and fingerprints away during repeated handling. This is useful when customers pick up a bar, read the label, and put it back. The sleeve keeps the soap presentable throughout the day.

A clean layout still matters even when the wrap is transparent. The paper sleeve choice suits brands that want printed panels and a softer look, while clear sleeves keep the bar visible from every side. If you use printed stickers, keep them small and place them on a flat area so they do not wrinkle. If you use ingredient cards, keep them trimmed so edges do not crease inside the wrap. This keeps bar soap plastic sleeves looking smooth and consistent in photos.

Cold Process And Melt Pour Clear Sleeve Uses Guide

Plastic soap sleeves for cold process soap are often chosen because cold process bars can have textured tops or angled edges that show nicely through clear film. A basic bar wrap approach helps when you want a simple wrap that keeps the bar clean without adding extra bulk. For stalls, a simple wrap also makes it easy to restock quickly when the table gets busy. Keep the sleeve size stable across your main bar sizes so packing stays faster.

Clear sleeves for melt and pour soap work well when the bars have transparent layers, embedded shapes, or bright colors. Using size modifications helps when bars vary by mold type, seasonal shapes, or thicker layered designs. A small allowance prevents corner stress and keeps the sleeve from pulling tight on edges. Keep any label area flat so it stays readable, and keep seals smooth so the wrap does not look wavy in photos. This supports custom soap sleeve packaging that looks neat on both shelves and online listings.

Common Selling Points For Clear Sleeve Packaging

- Shoppers see swirls, herbs, and layers without opening

- Bars stay cleaner while customers handle and compare

- Display looks organized for tables and retail shelves

- Multiple scents can keep a consistent presentation

- Wrapping stays quick when sizes are standardized

Packing Routine For Market Stalls And Online Orders

- Wrap bars the night before and store them flat in trays

- Keep labels or cards pre-cut so they slide in smoothly

- Separate scents with dividers to reduce rubbing marks

- Keep barcode areas flat and away from creases

- Carry spare sleeves for fast rewrapping during the day

| Selling Need | Clear Sleeve Detail | Label Approach | Storage Tip | Works Well For |

|---|---|---|---|---|

| Visual Appeal | Full bar visibility | Small flat label | Flat trays | Swirled soaps |

| Clean Handling | Film barrier | Belly band | Divider boxes | Busy stalls |

| Quick Restock | Standard sizes | Pre-cut cards | Stack flat | High volume |

| Gift Ready | Smooth finish | Minimal tag | Keep dry | Bundles |

| Online Photos | Consistent look | Quiet label area | Avoid creases | Listings |

Choosing Clear Sleeves For Branding And Compliance

Clear sleeves can still support branding when you place information in the right spots and keep the bar visible. A controlled label area helps buyers find scent names, weights, and key notes quickly without covering the design. The material types range helps you compare options when you also use cardboard soap sleeves, paper wraps, or other formats across your line. If you sell bundles, clear sleeves can pair well with Custom soap boxes wholesale while keeping the single bars visible and tidy inside sets. This creates a consistent look from single bars to gift packs.

Clear packaging sleeves for soaps also help with practical needs like barcode scanning and batch tracking. The transparent packaging styles approach supports simple product presentation where the soap stays visible and the information stays easy to find. Keep barcodes on a flat back zone, leave margin space around the code, and avoid placing it on a fold line. If you add ingredient cards, keep them trimmed so corners do not cause bulges. This keeps the sleeve looking smooth and helps scanning stay reliable at checkout.

Comparing Clear Sleeves With Paper Wrap Options Now

Clear sleeves are often chosen for visibility and clean handling, while paper wraps are chosen for a printed brand feel. The style based sleeves category helps you decide whether you want a full clear wrap, a mixed style, or a format that supports extra branding space. If your soap has a strong visual story, clear sleeves keep that story visible. If your brand relies on printed panels, paper formats may give more room for typography and artwork. The right choice depends on where you sell and how buyers interact with your products.

For humid climates or wet environments, waterproof formats can matter, and for craft stalls, visibility can matter more. Clear sleeves also help when customers ask voice-style questions like “How do I keep handmade soap clean at a market” or “What wrap shows the soap design clearly.” A direct answer is simple: keep the bar visible, keep handling clean, and keep labels flat and readable. If you use a band or label, keep it minimal so the soap remains the focus. This supports soap sleeve packaging and reduces rewrapping during busy selling hours.

Details That Keep Clear Sleeves Looking Professional

- Keep seals neat and aligned so edges look straight

- Use consistent sizes for your main bar formats

- Keep label areas flat with clean margins

- Store sleeves flat to prevent waves and creases

- Separate bars with dividers to reduce scuffing

Ordering Checklist For Fast Turnaround And Quality

- Share bar measurements and any shape details upfront

- Confirm the wrap style and closure method you prefer

- Decide where labels, bands, or cards will sit

- Test a small batch to confirm fit and photo look

- Finalize quantities based on stall and online demand

| Quality Check | What To Review | Quick Fix | Outcome | Helps With |

|---|---|---|---|---|

| Fit | Twisting or looseness | Adjust size allowance | Straighter panels | Shelf look |

| Seal | Uneven edges | Align closure method | Cleaner finish | Photos |

| Label | Wrinkles or bubbles | Use flat zone | Better readability | Buyer trust |

| Storage | Creases | Store flat | Smoother sleeves | Packing speed |

| Shipping | Scuffs | Use dividers | Cleaner bars | Delivery |

We at Soap Sleeves offer Plastic Clear Soap Sleeves at wholesale prices with coating options like Gloss, Matte, and Spot UV for printed elements when needed, plus free design and shipping on qualifying orders. Custom sizes and styles are available, along with fast turnaround times and high-quality material and printing options so your wraps stay neat from packing to delivery.